The Design to Manufacturing Experts

You've Got Questions, We've Got Answers

While you are waiting, check out our Resource Center or read our Blog!

Trusted by Startups and Global Brands for Over 25 Years

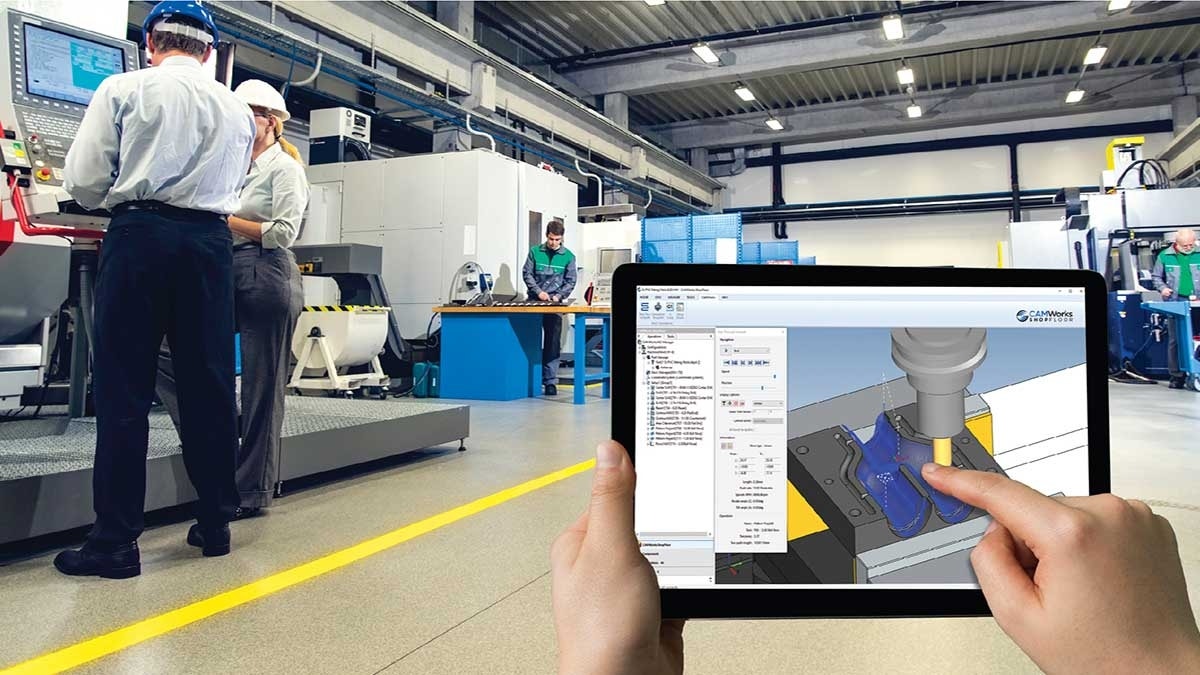

Premium Software, Hardware, Services, and Training

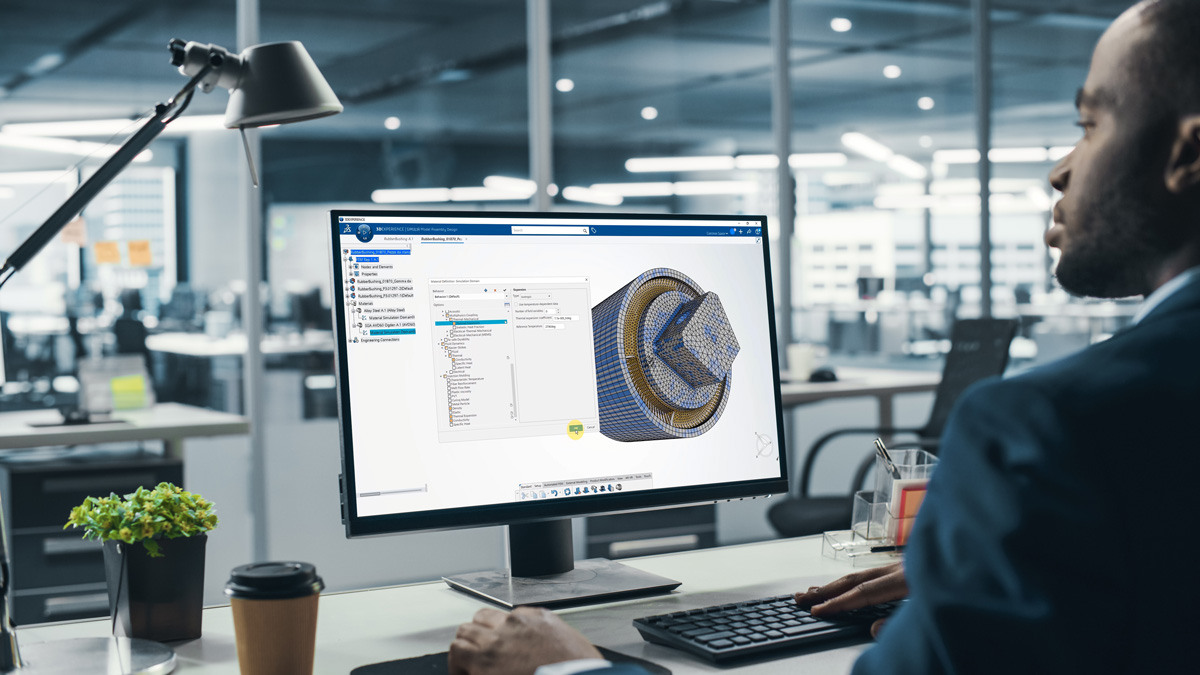

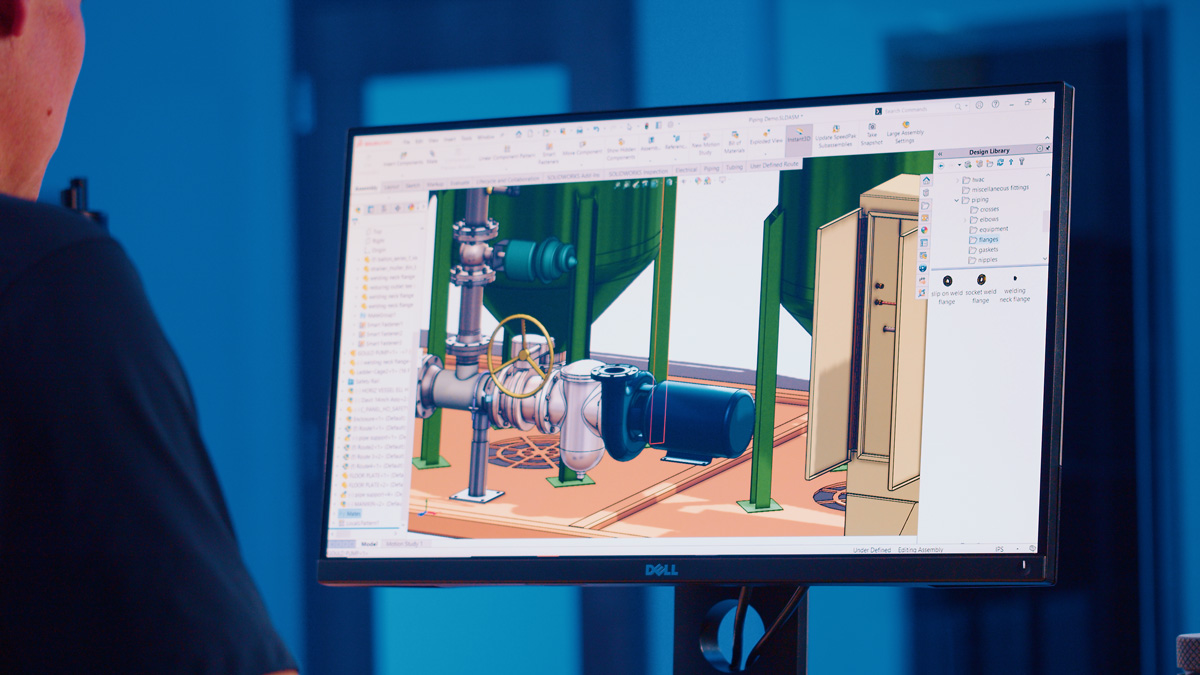

Engineering Software

3D Printers & Scanners

Support & Services

Professional Training

Platinum SOLIDWORKS Partner

#1 CAMWorks Provider Worldwide

#1 Markforged Provider North America

Certified HP 3D Printing Partner

World-Class Service & Support

Leading the way in engineering, manufacturing, and 3D printing, our commitment to excellence permeates every aspect of our operations.

However, it’s our holistic approach that truly sets us apart. Beyond technical prowess, our dedicated support team stands ready to accompany you throughout the entire lifecycle – from conceptualization to realization. Through our comprehensive service and support, you’re not merely a client but a valued partner.

Every. Single. Step.

Engineering Process Audit & Consulting

White-Glove Implementation

Best Practices and Guidance

Training and Continuing Education

What Our Customers Say

Nigel Linden

The support that I get from Hawk Ridge Systems is amazing. If I have any questions, I pick up the phone and I'm usually back up and running within minutes, it's wonderful. The people here are very knowledgeable.

Casmir Sienkiewicz

We've been working with Hawk Ridge Systems since the beginning and their support and training is awesome! When we need help they're always right there for us.

Denny Reiland

I just could not even begin to say enough about the great service we get from Hawk Ridge Systems. The service and support from Hawk Ridge is amazing.

Nick Keskey

Hawk Ridge Systems training was super easy to work with. The instructor was very easy to talk to. The class sizes were about ten people and after taking those courses I felt confident using SOLIDWORKS Simulation.

Don Schoendorfer

Working with the team at Hawk Ridge Systems has been invaluable. We haven’t run into an issue that their support team cannot solve. It really puts our organization at ease knowing we are well taken care of.

Better Engineering Starts Here

Free Events

Customer Stories

Pro Tips & Guides

Advice & How-Tos

More Than Just a Pretty Wheel – Forgeline

Watch Video

An Evolving Company - Knapheide

Watch Video

Right on Track - Pezo Solutions

Watch Video

Predict Your Design’s Real-World Behaviors

Watch Video

Selecting the Right 3D Printer

Download Guide

Your 3D CAD Buyer's Guide

Download Guide

What is the 3DEXPERIENCE Platform?

Read Article

SOLIDWORKS PDM: Don’t Waste Your Best Work

Read Article